For a while now I have been tracking yeast propagation data in a big spread sheet. But not every yeast propagation gets logged in there since I don’t always bother about taking cell counts.

However, I do have a few data points that are of interest when it comes to pitching yeast by weight and calculating starter volumes. The latter I’ll save for another day.

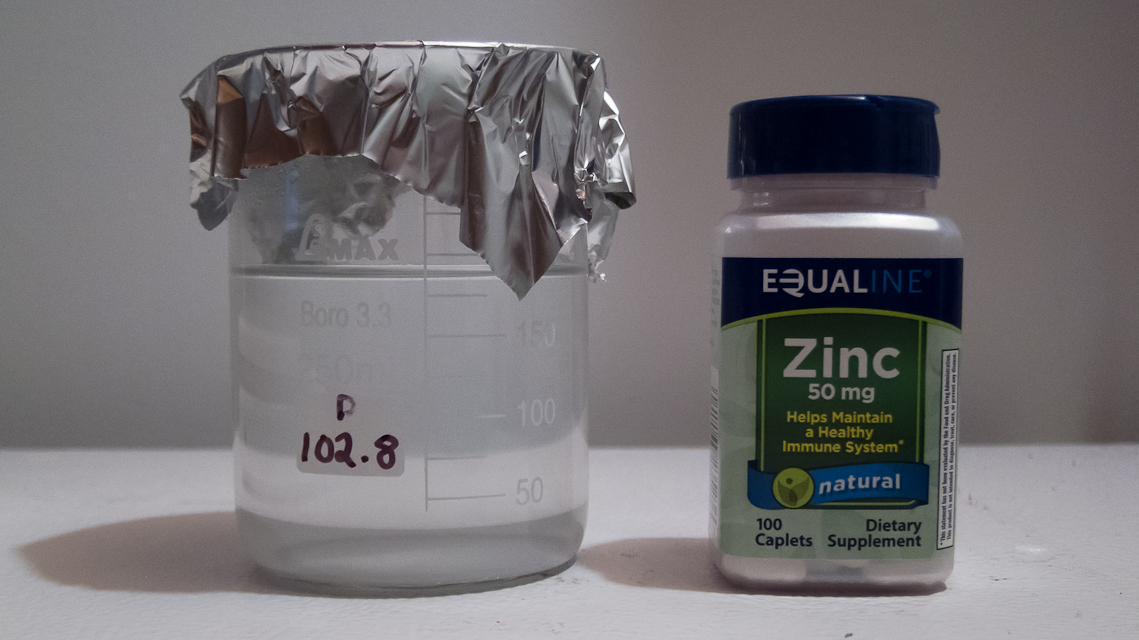

The idea of pitching by weight relies on having reasonably accurate idea of the cell count per gram of yeast slurry. With this the cell count can be estimated from the yeast slurry’s weight. Weighing of propagated yeast is simple if you know the weight of the propagation vessel (for most brewers that will be an Erlenmeyer flask). It’s a good idea to mark the empty weight on the flask. You should also note the weight of the stir bar if you are using one. You should stir your starters.

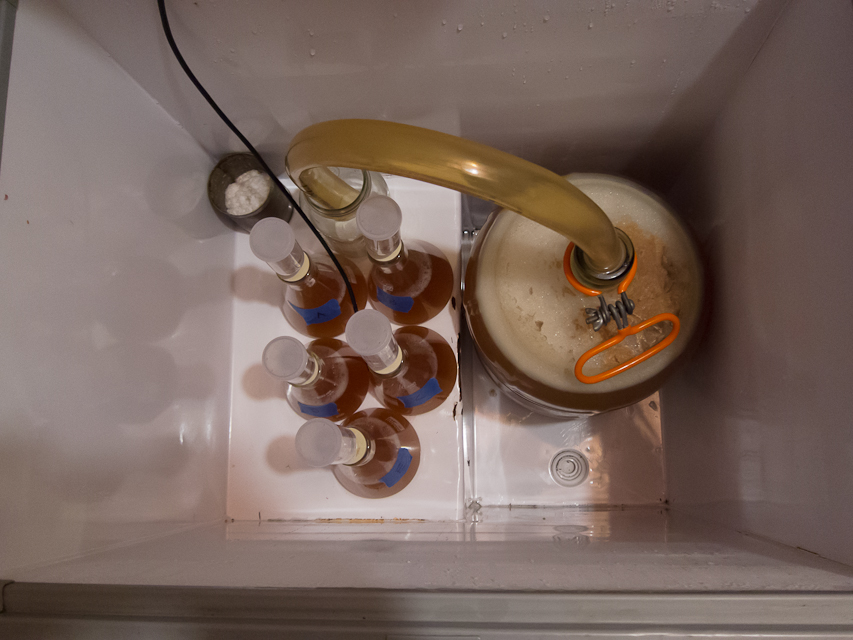

Simply decant the spent starter beer until left with yeast sediment and stir bar. This works best with strains that floculate well. Weissbier yeast, for example doesn’t settle into a dense sediment and you’ll loose some slurry during decanting or have to leave a fair amount of starter beer in the sediment.

Simply decant the spent starter beer until left with yeast sediment and stir bar. This works best with strains that floculate well. Weissbier yeast, for example doesn’t settle into a dense sediment and you’ll loose some slurry during decanting or have to leave a fair amount of starter beer in the sediment.

Then weigh the flask, subtract flask and stir bar weight and you have the yeast sediment weight.

That also works for washed yeast. If you don’t wash yeast and want to use the yeast sediment from a primary, turn the carboy upside down and let the yeast drip into a sanitized cup or beaker.

But how much yeast is in that sediment?

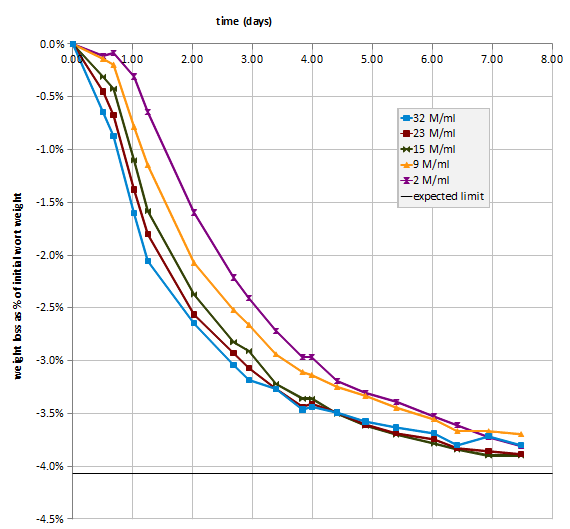

Here is some data I have:

- freshly propagated WLP 830 sediment contains about 4.5 Billion cells per gram. I have 4 data points ranging from 4.0 to 4.9 B/g. My starters have very little trub since I use leftover wort that has already been boiled for 60+ min

- harvested WLP 830 contains about 2.5 Billion cells per gram. I don’t get much trub into the fermenter. Virtually no hot break and maybe 50% of the cold break.

- I have only two data points for freshly propagated WLP 833. The average is 3.8 B/g. This can safely be rounded up to 4 B/g

- WLP 001 and WY 1272, both American Ale type yeasts, showed about 2.5 B/g in freshly propagated yeast sediment. These yeasts flocculate well and the sediment was as dense as the sediment for WLP 830/833. The yeast cells might just be a bit bigger than lager yeasts. I haven’t compared them under the microscope.

- The only top crop data I have is for WY1272 and that showed 2.7 B/g, which is close to the freshly propagated sediment. I would expect that washed yeast sediment has about the same density.

That’s all the reliable data I have. I have used English ale yeast (WLP 002), but that one flocculates so strongly that I was not able to count yeast cells.

The little data I have suggests that clean lager yeast sediment contains almost twice the number of yeast cells than comparable ale yeast sediment and that harvested sediment has about 60% the cell count of clean sediment.

Feel free to use these numbers as guidelines and keep in mind that being off from the actual yeast count by +/- 25% should not be a big deal. Most pitching rate experiments where brewers evaluated under and over pitching where done with 0.5x, 1x and 2x the recommended pitching rate or an even greater spread.

If you have sediment density data of your own, that you are willing to share, feel free to do so.