Yeast Propagator

Contents[hide]MotivationIt is well known that yeast propagation is best done with plenty of oxygen for the yeast. While this doesn't cause the yeast to start aerobic metabolism of sugars, the sugar concentration in worts brewers are using for yeast propagation is high enough to inhibit aerobic metabolism, the added oxygen is still beneficial for yeast since it can create and store more sterols for healthy cell walls. In the oxygen depleted environment of brewing fermentation sterol reserves are equally divided between mother and daughter cell when a daughter cell buds. This can lead to less than optimal sterol levels in yeast after the growth phase. Unfortunately this is when adequate reserves are needed for sufficiently strong cell walls to withstand the increasing alcohol concentration. During the early phase of yeast propagation on a stir plate, the starter beer will be saturated with air O2 at a level of about 8 ppm. This is a result of the vortex, which is formed, and the constant mixing of the beer with head space air. As yeast growth progresses and CO2 develops, the O2 concentration in the head space gradually declines. In addition to that a Kraeusen forms, which also inhibits the contact between air and beer. Inspired by the design of the Carlsberg Flask[1][2], a yeast propagator that can be completely sterilized before the yeast is added and which also allows for aeration before and during the propagation, I wanted to build something similar. These were the requirements:

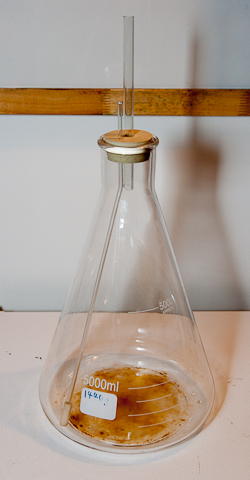

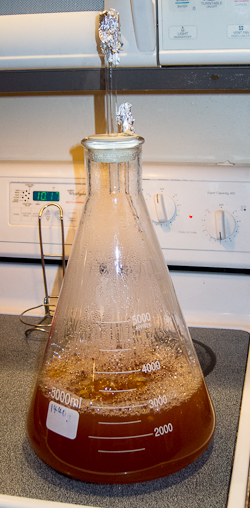

design and useWhat I ended up with is this simple device shown on the right. It uses a 5000 ml Erlenmeyer flask that can be purchased at Morebeer.com for only $40. The size 12 stopper is foodgrade (also available at Morebeer) and has two holes, which need to be drilled. One for a large glass tube, to which a blow-off hose will be connected, and another smaller tube to which a sterile air filter and an aquarium air-pump will be connected. The stock for the glass tubes was bought at cynmar.com. Bending the small tube over a flame allows it to be out of the center of the flask where a magnetic stir bar is stirring the wort. An aquarium air stone fits perfectly over its end. Initially the blow-off was supposed to be a bent glass tube as well, but it is very difficult to bent a glass tube more than a few degrees without kinking it. The wort and the propagator are sanitized on the stove top through boiling. Care must be taken such that the boil is not too vigorous and blows off through the blow-off tube. The glass parts may also be sanitized with a chemical sanitizer like StarSan, but sanitizing the device and the wort at the same time is the great advantage of using heat resistant glassware. This shows the hook-up of the aquarium pump through sterile air filters. This pictures shows two of these filters in series, which is not necessary. A little valve, which can be bought at an aquarium supply store, is used to control the air flow from the pump into the filter. This allows for adjustment of the air flow and reduction of foaming inside the flask. When the starter is fermenting, or simply releasing CO2, and the blow-off tube is submerged in water or could become clogged, the air supply should never be shut off without completely pinching off the air hose or by using other means of preventing beer from being pushed through the air store and into the air hose and filters. A check valve, which should be available in aquarium supply stores may useful as well. The yeast propagator in action. Air is pumped into the propagator at a slow rate while the beer is stirred to keep the yeast in suspension. Excess Kraeusen is blown-off. Due to the increased formation of Kraeusen, after all bubbles are created by the air, this form of propagation is only suited for bottom fermenting yeast which does not rise into the Kraeusen. Top fermenting yeast rises into the Kraeusen and too much would be blown off.

On the right is a close-up of the air stone and the bubbles rising from it. The stir plate is off, hence the layer of yeast sediment at the bottom. When yeast propagation is complete the air hose is disconnected and the propagator is placed in the fridge to allow the yeast to settle. When the yeast is ready to be pitched the spent starter beer is decanted and the flask with yeast cake and stir bar is weighed. With the empty weight of the flask and stir bar known, the weight of the yeast cake can be calculated. Each gram of freshly propagated yeast (minimal trub content) contains about 4-5 Billion cells. 20 l (~ 5 gal) of 12 Plato lager beer require about 90 - 100 g of yeast sediment for pitching. PerformanceThe yeast per extract grain with this set-up (1.5 - 2.0 Billion new cells per gram of extract) appears to be slightly higher than what is gained without constant aeration but constant stirring (1.2 - 1.6 Billion new cells per gram of extract). Those numbers were taken from records kept for various forms of yeast propagation. References

|