Recently I gave a pack of my homegrown hops to a friend of mine who regularly brews at a Deja Brew, a Brew on Premise place in Shrewsbury Mass. The quality of the hops, including the fact that they retained their fresh green color, was especially noted by the owner who commonly sees customers with poorly dried and stored home grown hops. So I decided to outline my process here. While this process may be standard operating procedure for most of my regular readers there might still be a few pieces of new information here and there.

When to pick

Hops grown in he Northeast are generally ready to pick towards the end of August. What I’m looking for are well developed lupulin glands, the yellow grains at the base of the cone’s leaves, a distinct fresh hop aroma when rubbed between palms and a papery/springy feel when the cone is squeezed. A few cones may already have brown tips on their leaves. The time window for picking them might be 1 to 2 weeks.

It is important that hops are not picked too early since, just like fruit, hop cones ripen and develop some of their characteristic flavor later in their life. This includes the synthesis of sesquiterpenes Humulenne and Caryophyllene, which are the 2nd and 3rd largest constituent of the hop oil. The major constituent, mycrene, is already produced in young cones. 1)

When I’m ready to pick cones I don’t pick them selectively. I generally cut off pieces of the bine, as hop “vines” are called, starting from the top so I can stop when enough cones were picked. All cones are generally picked within a week.

Freshly picked hops

How to dry

In order to prevent rotting, the picked hops need to be dried immediately. And when it comes to hop drying, we home hop growers actually have an advantage over commercial growers. This advantage lies in the ability to dry hops with ambient air temperature. Some of the hop oils we are trying to preserve have flash points around 100 F (40 C) and the application of heat during drying would volatilize and drive them off 2). In fact I seem to be getting better and different aromas from my home grown Cascade compared to store bought Cascade.

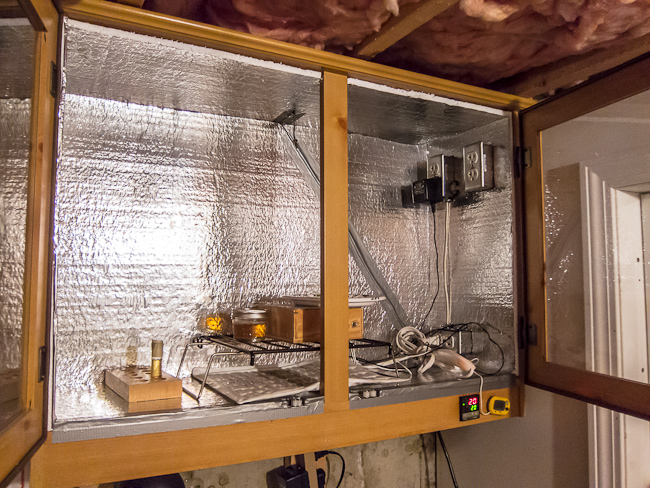

In my opinion, drying is best done using a dedicated oast. Some brewers dry hops in the oven, which I don’t recommend due to the high temperatures. Others spread the hops on window screens. I don’t like that option since it takes up lots of space.

The hop oast I built is very simple. It consists of racks build from 2x4s and window screen that can be stacked on top of each other and placed on top of a window box fan. The fan blows air through the hops from the bottom and I place the least dry batch on the top and the most dry batch on the bottom. Since the air is forced through the hops they can be packed more tightly and the whole contraption does not take up much space. A batch of hops dries within 3 days in that oast.

Hops are dry enough once you can squeeze a handful and they do not feel damp anymore. In addition to that the stem should easily snap. This is the part that takes the longest to dry.

simple oast for efficient hop drying

Packaging and storage

Vacuum packed dried hops

Hops are best stores in a vacuum sealed package. I highly recommend the investment into a vacuum sealer like the FoodSaver line of products. Oxygen is the main enemy of hops and while a vacuum sealer does not eliminate oxygen it greatly reduces oxygen during hop storage. I generally make 120 g (4 oz) packs of hops. It’s useful to make the hop bag larger than it needs to be for two reasons. First, it makes it easier to stuff the rather bulky dried hop coned into the bag and second, the bag can easily be vacuum packed and re-sealed once opened. I also recommend labeling the hops bag an the end that will not be cut off and not like it is done in the picture on the right.

Hops should be stored in the freezer since the low temperatures slow staling reactions. This also keeps them out of the light.

If you follow these recommendations you will see that the quality and shelf life of your home grown hops is on par or better compared to store bought hops.

Due to the unknown of the actual alpha acid content, home grown hops are best used as late hop additions for for dry hopping.

Update:

A few weeks after writing this I listened to a great Basic Brewing Radio interview with Dan Dettmers of Gorst Valley Hops. Look for the September 27, 2012 eposide in the 2012 list of episodes.

References:

1) Peter Wolfe, A Study of Factors Affecting the Extraction of Flavor when Dry Hopping, 2012

2) Joseph Wegner, Gorst Valley Hops, The Science Behind the Art: Hops in Brewing, presentation at the 2010 American Homebrewers Conference